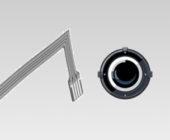

Custom Lens Unit for Warehouse Inventory Recognition

Detail Information

| Application: | Image recognition |

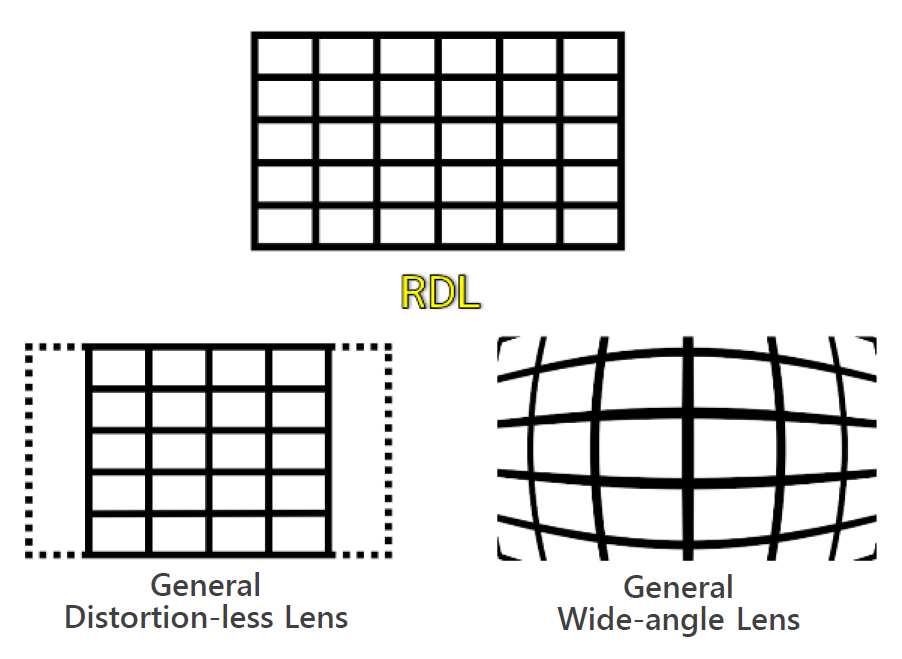

| Part/Product: | Warehouse Inventory Recognition Camera |

| Industry: | Automotive & Transportation |

| Dimension: | L28mm x Φ32mm |

| Function: | Warehouse Inventory |

| Delivery Timeline: | - |

Challenges Before Implementation

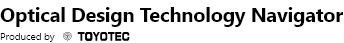

When capturing images of a large area at a limited distance from an object, the customer had difficulty calibrating the software to correct the distortion of the images captured with a wide-angle lens. With ultra-wide angle lenses such as fisheye lenses, the edges of the image were shrunk, making it difficult to recognize feature points, and correcting distortion in high-resolution images caused delays in the real-time image.

Why TOYOTEC and RDL?

We received an inquiry about RDL through an introduction of VR/AR system development company that was aware of the customer’s challenges and TOYOTEC’s technology. In addition, TOYOTEC is capable not only of designing special lenses such as RDLs, but also of customizing design specifications to meet the customer’s needs.

Prospects for the Future Based on the Effects and Changes Resulting from the Introduction of the System

Although we are still in the introduction study stage, the actual test simulation has reduced the burden of calibration for distortion correction. We have received feedback that this technology will become even more necessary with the introduction of high-resolution cameras in the future.

Related Solution-Application

Micro Cylindrical Lens fo

What is Toyotec's Micro-Cylindrical…

Micro Cylindrical Lens Te

Development Story “We wanted…

Plastic Laser Reflective

Challenges Before Implementation A…

Specially Shaped Plastic

Challenges Before Implementation The…

Plastic Lens Units for So

Challenges Before Implementation The…

Glass Lens for Ophthalmic

Challenges Before Implementation The…

Reference Development Cas

Do you have any…

Ultra Low Distortion Cust

Challenges Before Implementation When…

JP Phone: 0533-85-3000

JP Phone: 0533-85-3000