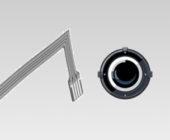

Specially Shaped Plastic Lens for Infrastructure Measurement Meter

Detail Information

| Application: | Optical Detection |

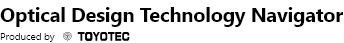

| Part/Product: | Specially Shaped Plastic Lens |

| Industry: | Other Industries |

| Dimension: | φ20 x 5mm thickness |

| Function: | Detect Analogue Indicators |

| Delivery Timeline: | - |

Challenges Before Implementation

The customer was considering introducing an optical technology to detect and measure the pointer of a measuring instrument. However, when the customer commissioned the design from a consulting firm specializing in optical design, the customer could not find a manufacturer that could produce the product according to the design drawings because the manufacturing expertise was not considered.

Why TOYOTEC?

Since TOYOTEC has experience in the design, prototyping and mass production of custom plastic lenses and precision molded products, we were asked to optimize design and production with manufacturability in mind.

Prospects for the Future Based on the Effects and Changes Resulting from the Introduction of the System

TOYOTEC proposed an optimal optical design that met the customer‘s specifications and took manufacturability into consideration to achieve the production. The specially designed plastic lens maximized the amount of the light received by the sensor, which detected the pointer even in low-light conditions. (TOYOTEC patented technology)

Related Solution-Application

Micro Cylindrical Lens fo

What is Toyotec's Micro-Cylindrical…

Micro Cylindrical Lens Te

Development Story “We wanted…

Plastic Laser Reflective

Challenges Before Implementation A…

Plastic Lens Units for So

Challenges Before Implementation The…

Glass Lens for Ophthalmic

Challenges Before Implementation The…

Reference Development Cas

Do you have any…

Custom Lens Unit for Ware

Challenges Before Implementation When…

Ultra Low Distortion Cust

Challenges Before Implementation When…

JP Phone: 0533-85-3000

JP Phone: 0533-85-3000