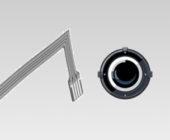

Micro Cylindrical Lens for LiDAR Emitter systems (Laser Scan Type)

Detail Information

| Application: | Laser Projection, Measurement |

| Part/Product: | ・Beam shaping for semiconductor laser diodes (FAC/SAC) ・LiDAR (laser scanner) projection systems |

| Industry: | Others |

| Dimension: | Less than R3、φ1mm |

| Function: | Optimization of beam quality, throughput, and cost efficiency in laser optical systems |

| Delivery Timeline: | Samples are available |

What is Toyotec’s Micro-Cylindrical Lens?

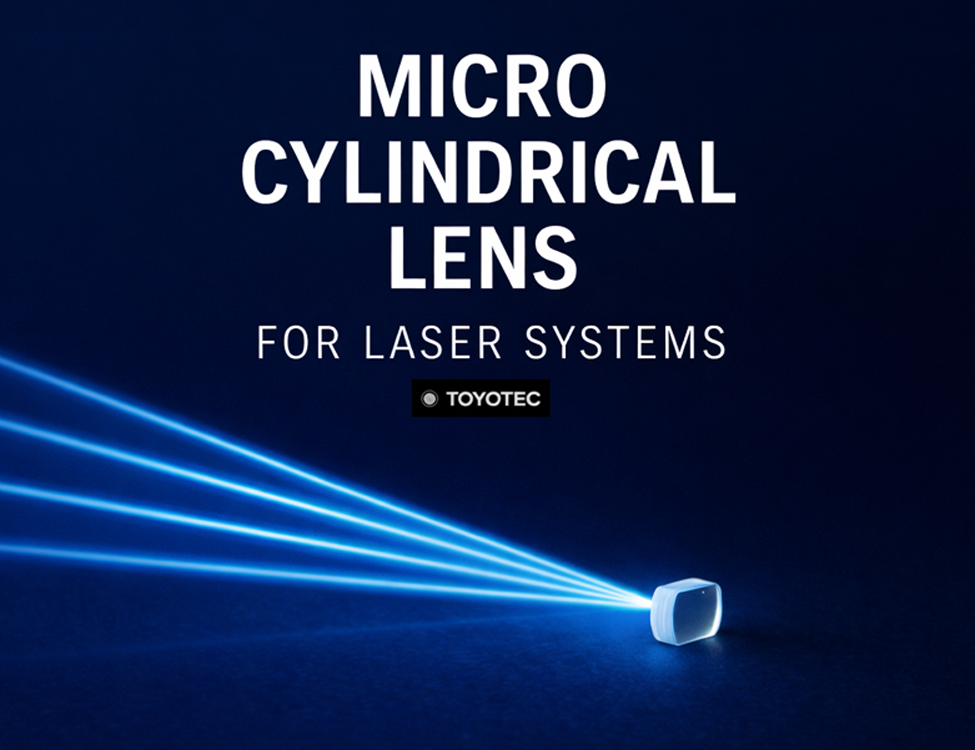

TOYOTEC’s micro cylindrical lens is manufactured using precision glass spherical machining, achieving an extremely small radius of curvature of R1.65.

With our proprietary processing technology, we realize high surface accuracy at the 0.3 µm level (less than one Newton ring / PV λ/2).

This technology delivers high optical performance while maintaining cost efficiency and suitability for mass production.

Challenges Before Implementation

The customer was seeking a micro cylindrical lens for LiDAR (laser scan type) emitter systems.

In particular, for FAC / SAC lenses used in LiDAR projection optics, they faced challenges related to performance limitations, cost constraints, and concerns over supply interruptions caused by geopolitical risks.

Why TOYOTEC?

Long-standing customers often say, “When it comes to cylindrical lenses, TOYOTEC is the first choice.

TOYOTEC is especially valued for its ability to provide practical, production-ready design proposals from the early development stage, based on the following strengths:

-Responsible support that goes beyond prototyping and extends through mass production

-Cost-effective solutions even for small production volumes enabled by proprietary processing technologies

-A strong sense of security backed by long-term mass production and stable supply performance

As a result, TOYOTEC is chosen as a partner that turns “not sure if it can be made” into “ready for mass production.

Prospects for the Future Based on the Effects and Changes Resulting from the Introduction of the System

TOYOTEC has supplied approximately 3 million cylindrical lenses per year for over 20 years, primarily to the OA market.

This long-term, high-volume supply record is clear evidence of our reliable glass cylindrical lens processing technology and robust mass production capability.

As a result, we have achieved the following:

– High reproducibility in small R machining

– Stable quality on mass production lines

– A highly reliable production system designed for long-term supply

Are You Facing Any of These Challenges?

If any of the following issues sound familiar, TOYOTEC is ready to support you:

-You want to pursue new technologies, but lack a supplier who will stay committed through the entire development process

-Minimum order quantities are too large, or suppliers cannot meet your required volume and cost targets

-Concerns about supply disruptions and geopolitical risks due to dependence on overseas or Asian manufacturing

-Uncertainty about long-term component supply caused by succession issues or aging management at small suppliers

👉 Contact TOYOTEC to discuss your requirements.

Related Solution-Application

Micro Cylindrical Lens Te

Development Story “We wanted…

Plastic Laser Reflective

Challenges Before Implementation A…

Specially Shaped Plastic

Challenges Before Implementation The…

Plastic Lens Units for So

Challenges Before Implementation The…

Glass Lens for Ophthalmic

Challenges Before Implementation The…

Reference Development Cas

Do you have any…

Custom Lens Unit for Ware

Challenges Before Implementation When…

Ultra Low Distortion Cust

Challenges Before Implementation When…

JP Phone: 0533-85-3000

JP Phone: 0533-85-3000