Micro Cylindrical Lens Technology with Small R(Curvature Radii)

Detail Information

| Application: | Laser Projection, Measurement |

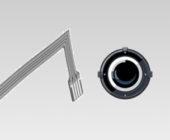

| Part/Product: | Micro glass cylindrical lenses for Laser diode and LiDAR |

| Industry: | Others |

| Dimension: | Less than R3、φ1mm |

| Function: | Optimization of beam quality, throughput, and cost efficiency in laser optical systems |

| Delivery Timeline: | Sample are available |

Development Story

“We wanted to create a truly unique lens processing technology—something only TOYOTEC could deliver to the world.”

That vision sparked the development of our new micro cylindrical lens solution.

TOYOTEC has long specialized in glass cylindrical lenses manufactured using a proprietary methods. This method allows for low-cost production of long cylindrical lenses and has been trusted by clients both in Japan and overseas for decades. Now, the original inventor of that technology has teamed up with engineers in both Japan and China to adapt and refine the process for high-precision micro cylindrical lenses, taking it all the way to mass production.

We had received many customer inquiries over the years regarding micro lenses. However, the only available method for us was glass molding, which came with initial cost challenges.We always believed there must be a better alternative—something more flexible and cost-effective—and that belief is what led us to this innovation.

What Is Micro Cylindrical Lens for High-Precision Beam Shaping?

TOYOTEC is developing high-precision micro cylindrical lenses with small curvature radii (R), optimized specifically for laser applications.

This new technology is based on our proprietary manufacturing methods that does not require glass molding.

It achieves submicron-level surface accuracy, making it possible to fabricate deep-R geometries that are difficult to produce using conventional polishing techniques.

These lenses are ideal for:

・Beam shaping in semiconductor laser and LiDAR applications

・Enhancing fiber coupling efficiency and sensor ranging accuracy

・Simplifying optical design while ensuring compatibility with high-volume manufacturing

In addition, these lenses can serve as high-precision preform materials for molded aspherical glass lenses, where precise initial surface accuracy contributes to better molding quality and improved cycle stability.

Key Advantages:

✅ No need for glass molding → Reduces tooling and initial investment costs

✅ Improved beam uniformity → Increases production yield

✅ Greater design flexibility → Enables compact optical module integration

✅ Useful as glass molding preforms → Ensures high form fidelity and repeatable performance

Sample are available now.

If you’re exploring high-performance and cost-efficient solutions for laser beam control or glass preform supply, please don’t hesitate to contact us.

👉 Contact us here

Related Solution-Application

Micro Cylindrical Lens fo

What is Toyotec's Micro-Cylindrical…

Plastic Laser Reflective

Challenges Before Implementation A…

Specially Shaped Plastic

Challenges Before Implementation The…

Plastic Lens Units for So

Challenges Before Implementation The…

Glass Lens for Ophthalmic

Challenges Before Implementation The…

Reference Development Cas

Do you have any…

Custom Lens Unit for Ware

Challenges Before Implementation When…

Ultra Low Distortion Cust

Challenges Before Implementation When…

JP Phone: 0533-85-3000

JP Phone: 0533-85-3000