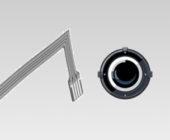

Plastic Lens Units for Solid State LiDAR for Industrial Applications

Detail Information

| Application: | AGV(Automatic Guided Vehicle) |

| Part/Product: | Solid State LiDAR |

| Industry: | Automotive & Transportation |

| Dimension: | H21mm x W15mmx L22mm |

| Function: | Obstacles for Automated Vehicles |

| Delivery Timeline: | 3 - 4 months |

Challenges Before Implementation

The customer was looking for projection and receiver lens units for an anti-collision safety sensor for a small AGV.

They needed design and manufacturing technology using plastic lens units to reduce the size and weight of the product, but lacked the internal resources for in-house design, so they needed a supplier with design expertise who could consider the manufacturability of plastic parts and also provide optical evaluation.

Why TOYOTEC?

Since TOYOTEC has experience in the design, prototyping, assembly, and mass production of plastic lenses and precision molded products, we were asked to optimize the design for manufacturability, build our own evaluation machine to simulate the product environment and verify the evaluation criteria, and the mass production of the products.

Prospects for the Future Based on the Effects and Changes Resulting from the Introduction of the System

We have maintained stable mass production of more than tens of thousands of pieces per year. For more than 10 years, we have contributed to the production realization of optical designs demanded by our customers with our design and development capability based on our rich experience and high production capacity.

Related Solution-Application

Micro Cylindrical Lens fo

What is Toyotec's Micro-Cylindrical…

Micro Cylindrical Lens Te

Development Story “We wanted…

Plastic Laser Reflective

Challenges Before Implementation A…

Specially Shaped Plastic

Challenges Before Implementation The…

Glass Lens for Ophthalmic

Challenges Before Implementation The…

Reference Development Cas

Do you have any…

Custom Lens Unit for Ware

Challenges Before Implementation When…

Ultra Low Distortion Cust

Challenges Before Implementation When…

JP Phone: 0533-85-3000

JP Phone: 0533-85-3000