What Are the Points in Choosing Between Catalog / Custom Lenses?

Have you ever thought about using optical lenses for your product and thought, “There are so many different types and prices to choose from. Which one should I choose?” Just as there are ready-made and order-made suits, there are catalog and custom lenses. In this column, we will introduce the characteristics of these two types of lenses and explain the key points to consider when choosing the lens that best suits your needs.

1. Types of Lenses

〇Catalog Lens

Refers to ready-made lenses sold on websites or in catalogs.

【Pros】

・Can be easily found and quickly purchased from catalogs and other sources

・Can be purchased in low quantities

・Wide lineup, ideal if you want to try out lenses with various specifications

・No initial investment needed for molds, jigs, evaluation machines, etc.

【Cons】

・There are cases where there is no match to the required specifications that you really want

・Even with higher purchase volumes, cost benefits are small

・It is hard to distinguish the product from others because anyone can purchase the product

・Specifications cannot be altered

〇Custom Lens

An order-made lens that is made based on the buyer’s specific optical performance and

specification requirements.

【Pros】

・It can be order-made

・Can meet the required specifications you want

・Specifications can be changed during the production process

(Though, it might cost additional fee during development phase)

・It is easy to generate cost benefits per unit when the purchase volume is high

・Even if you don’t have specific specifications, suppliers can work with you from

the product concept building stage

【Cons】

・It takes time

・There are initial costs for molds, jigs, evaluation machines, etc

・You have to provide a requirements specification

・Without optical knowledge, it is hard to know what to pay attention to and

what are the key points to manufacture a lens

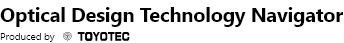

〇Summary of Catalog / Custom Lens Comparison

Knowing “what kind of lens you want, when do you want it, and how many do you want” is essential in selecting lenses. Therefore, one of the key points in avoiding problems in lens selection is to follow the above explanation.

2. Case Studies

〇Case 1

【Background】

This is a case in which TOYOTEC made a proposal to a customer who had purchased a catalog lens.The customer wanted to lower the unit purchase price, and asked TOYOTEC if the unit price could be lowered with a custom lens.

【Inquiry Details】

・Quantity:50 pcs / Month

・Product Life:10 Years(120 Months)

・Requirements:A lens unit using glass lenses, design / spec must be same as the current catalog lens

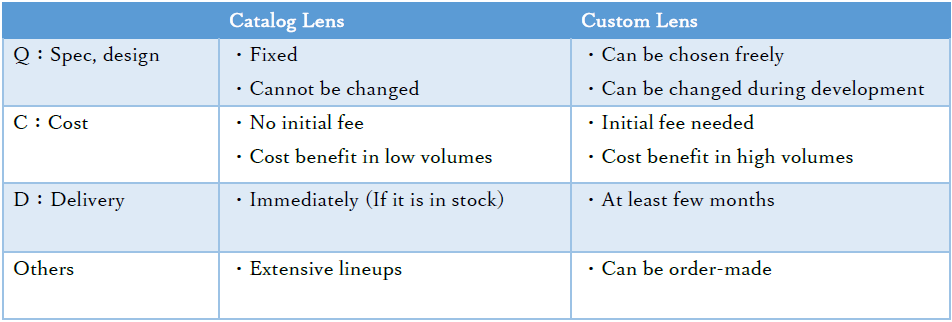

Figure 1: Comparison of Catalog and Custom Proposals

【Results】

The unit price of custom lenses was higher than the unit price of catalog lenses, and there was no benefit to the customer.

【Explanation】

As described in “1. Types of Lenses,” custom lens production requires initial costs for molds, lens jigs and tools, etc. In addition, if the quantity is small, it is difficult to reduce the unit cost of parts from that of a catalog lens. Under the customer’s requirements, there is no benefit in making custom lenses.

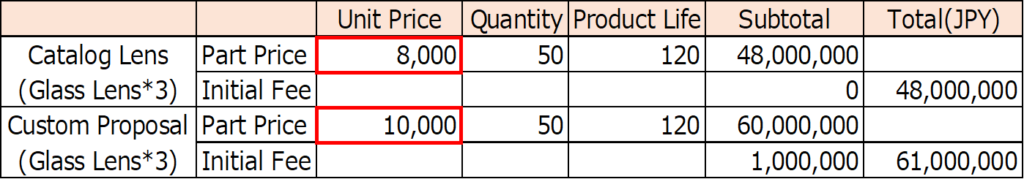

Figure 2: Cost Comparison of Catalog / Custom Lenses

However, as shown in Figure 2, the part cost decreases as the quantity of custom lenses increases, so when requesting custom lenses with a focus on cost, it is recommended that multiple quantity requirements be presented.

〇Case 2

【Background】

This is a case in which TOYOTEC made a proposal to a customer who had purchased a catalog lens as well as Case 1. This customer had requests to reduce product size while maintaining unit price and optical performance, and asked TOYOTEC if this was possible.

【Inquiry Details】

・Quantity:1,000 pcs / Month

・Product Life:5 Years(60 Months)

・Requirements:Production of a full lens unit. If optical performance can be maintained,

the design can be freely chosen by the supplier.

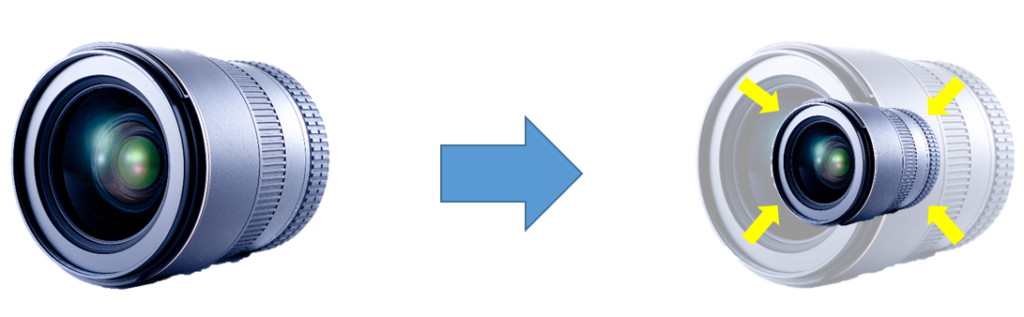

Figure 3: Lens Miniaturization Image

【Results】

TOYOTEC analyzed the current product and redesigned the lens. As a result, we were able todownsize the lens while maintaining the same unit price and optical performance, thus achieving the customer’s needs.

【Explanation】

Unlike Case 1, there are two reasons for the positive results. One is because the quantity requirements were relatively large,and the other is because we were able to work with the customer from the development stage.

Related Column

3. How to Avoid Problems in Custom Lens Production

As in the Case 2 of the previous chapter, there are cases in which choosing a custom lens can be beneficial, but just simply telling your needs may lead to problems in producing custom lenses. There has been cases where lens production proceeded according to the required specifications, but defects occurred at the stage just prior to prototyping or the mass production of the lens.

Lens making is a complex process involving a variety of factors. To prevent such problems, it is important to have a series of conversations with each other while keeping the following points in mind;

・Check if there are any flaws in the presented specification of requirements

・Disclose the environment in which the final product will be used as much as possible

・Share a clear image of the final product to the supplier

As shown in Figure 4, the lens development process begins with the conception of the final product, followed by the development of product specifications, optical and structural design to meet those specifications, and making the drawing. In some cases, we are able to make proposals that exceed the customer’s needs, especially if the customer is able to fully disclose the image of the final product at this initial stage of the development process.

*Optical Design…Design to fulfill optical specifications

*Structural Design…Design of mechanical parts such as lens barrel

It is also necessary to clarify the roles of the customer and the supplier in the custom lens development process. The patterns below can be considered for these roles. Regardless of the pattern, the above-mentioned points for avoiding problems remain the same.

Figure 4: Lens Development Process

However, you should be careful when procuring optical lenses and structural components separately. There are many factors in structural design that affect optical specifications, such as light leakage and stray light, pressure on lens surfaces due to assembly, and lens tilt, etc. Manufacturers who design and manufacture structural components are also required to have optical knowledge. Selection of a manufacturer without considering this point may also lead to defects prior to prototyping and mass production. When procuring optical lenses and structural components separately, one of the points to avoid problems is to consider the level of optical knowledge of the structural component manufacturer.

4. How to Avoid Problems in Lens Selection

Finally, I would like to explain the points to avoid problems in lens selection.

①Check if there are lenses that meet the required specifications by checking the lineup of catalog lenses.

②If there are no catalog lenses that meet the requirements, or there are only catalog lenses that fall short of the requirements, ask custom lens manufacturers for help.

③Provide the required specifications and share the image of the final product with the custom lens manufacturer as much as possible.

④Check how far each manufacturer is able to respond to your needs,and make a decision on the supplier of the order.

→In addition to the ability to design and manufacture the structural components mentioned above, there are two more key points to consider when making a decision; whether the company can manufacture molds and jigs and whether the company can design and manufacture dedicated evaluation equipment when elements that cannot be evaluated with general-purposeoptical measuring equipment are encountered.

5. Optical Design Technology Navigator Will Solve All Your Needs for Custom Lenses!

As described in “1. Types of Lenses,” there are advantages and disadvantages to custom lenses. TOYOTEC will propose custom lenses that meet your needs and minimize the disadvantages of custom lenses by utilizing our experience and know-how. Even if you are new to custom lenses, our experienced optical designers, structural designers, and sales engineers will consult with you from specification determination.

TOYOTEC, operator of the Optical Design Technology Navigator, is an all-around optical manufacturer with proficiency in optical, mechanical, and electronical technology. We can design and develop products from scratch based on our customers’ needs, and provides integrated support from design to productization. In addition to manufacturing custom lenses, we offer a one-stop service that includes the fabrication of molds and jigs and tools necessary for lens production, the design and assembly of the full lens unit including systems and structural components, and the design and manufacturing of specialized evaluation equipment.

If you are thinking about something like, “If only there was a product like this…”, or, “Is it possible to do these kind of things with lenses?”, Optical Design Technology Navigator, a website operated by a group of optical design professionals, is the place to go. If you have any questions about optical design, please feel free to contact us at Optical Design Technology Navigator.

JP Phone: 0533-85-3000

JP Phone: 0533-85-3000 Contact Us

Contact Us Language:

Language: