ODM / OEM

ODM Manufacturing

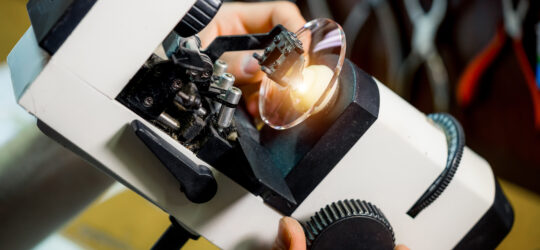

Optical Design Technology Navigator provides total support for ODM, from optical unit design to product development. We have a wealth of mold-making know-how based on more than 20 years of experience, and a large number of optical units that we have manufactured for a variety of industries over the years. Our customers are able to realize highly efficient production and higher profits by effectively using our technical capabilities and production system.

We also have experience in the development of various prototypes. Optical design products are rarely mass-produced immediately, and it is not until they have gone through the prototype development process many times that they are ready for mass production. At Optical Design Technology Navigator, we act as your partner in optical design technology, providing an integrated service from prototype development to mass production.

OEM Manufacturing

Optical Design Technology Navigator also supports OEM production of optical components and unit parts. If you provide us with design documents and drawings, we can start the mass production at two sites: in Japan and/or one site in China. We have many years of experience in manufacturing a wide range of optically designed units for leading Japanese manufacturers. This has enabled us to produce optical components with the highest efficiency based on industry standards.

However, if you consult with us from the design phase, we will be able to make all kinds of cost-cutting proposals to you as a group of optical design professionals. Our ability to make cost-cutting proposals is one of our strengths, so if you are considering OEM production, please contact Optical Design Technology Navigator to discuss your needs in advance.

High Quality / Low Price Manufacturing

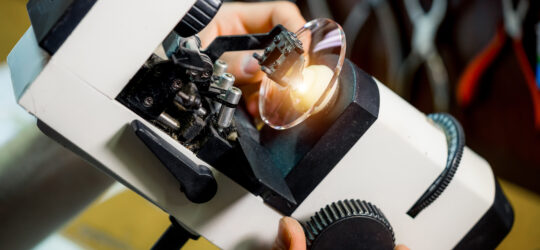

In addition to providing a stable supply of high quality, high precision components, we also offer optical components at low prices.

In order to respond to changes in markets and demands with a global system, our head office in Japan is focusing on design development, development of production technology elements, development of measurement technology, quality assurance, environmental management, and so on, with the factory in China as the production base. For this reason, we are able to consider production locations and production methods that meet the needs of our customers, e.g., China for mass production and Japan for small-lot high-mix production. Even in the midst of increasingly stringent cost requirements, we have a mass production system that enables us to manufacture products at low cost, based on the optical technology we have built up over many years.

In addition, some of our products are already manufactured in our factory in China, so we can produce them in an integrated manner, from tooling making to molding, in our factory in China. Our strength is that we can meet the needs of our customers with Japanese quality and Chinese prices.

Engineering Services

Lens / Lens Unit Development

Learn More

Design / Development Support

Learn More

JP Phone: 0533-85-3000

JP Phone: 0533-85-3000