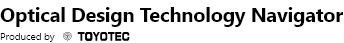

Laser-Reflexionsspiegel aus Kunststoff

Detaillierte Informationen

| Anwendungen: | Laserprojektion, Messung |

| Teil/Produkt: | Laser-Reflexionsspiegel aus Kunststoff |

| Industrie: | Andere |

| Abmessung: | 140mm x 70mm |

| Funktion: | Objekterkennung, Barcode-Leser |

| Lieferfrist: | 6 Monate |

Herausforderungen vor der Implementierung

Ein Spiegelelement, das zum Scannen von Objekten, wie z. B. Barcodes, durch Abtasten von Laserlicht verwendet wird.

Kunden, die bisher Spiegel aus Metall oder Glas verwendet haben, waren besorgt darüber, "ihre Produkte leichter zu machen" und "die Kosten zu senken“

Warum TOYOTEC?

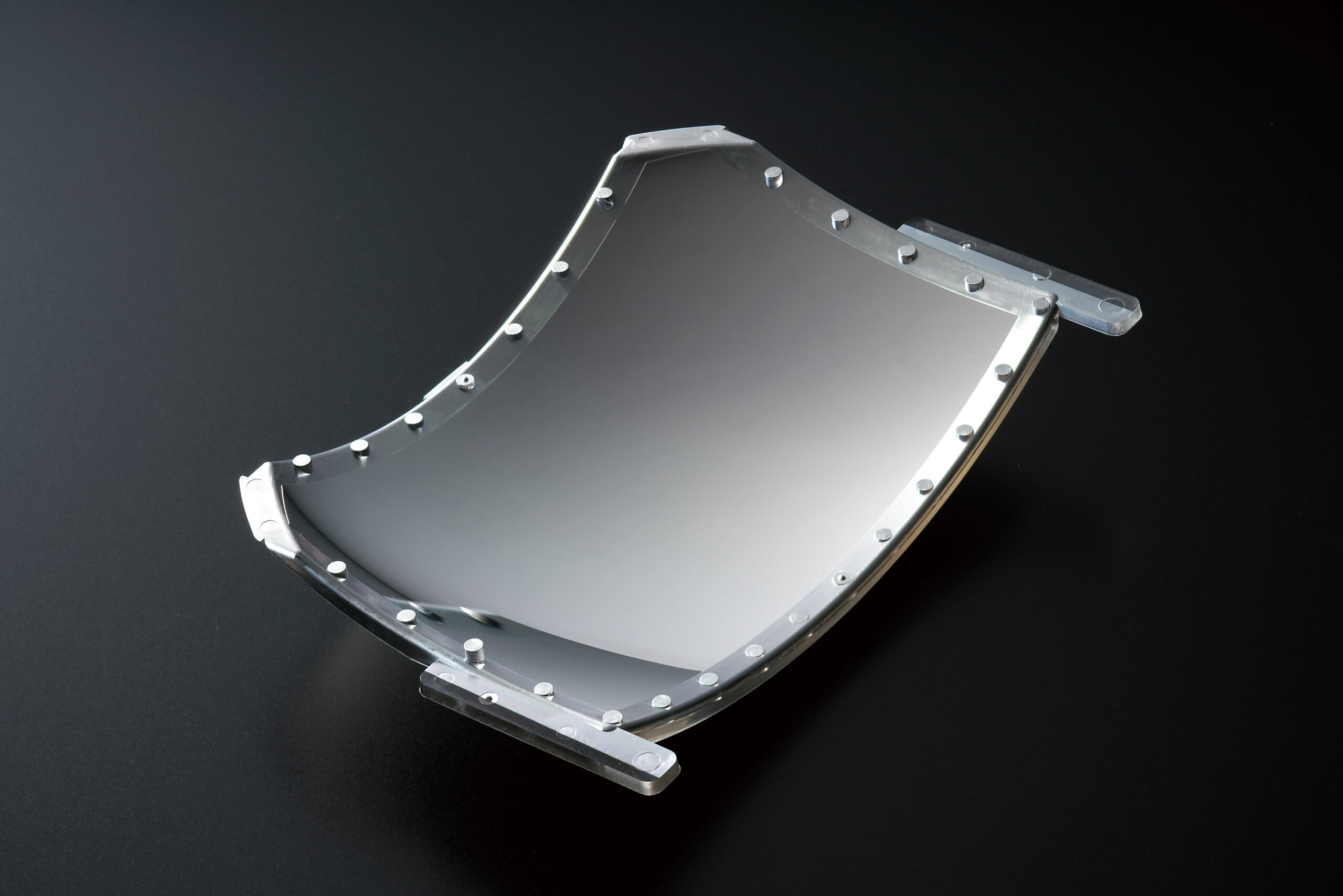

Bei Toyotec können wir einen umfassenden Inhouse-Service anbieten, von der Herstellung von Formwerkzeugen zur Formung der Spiegeloberfläche der Kunststofflinse (der Prozess der Formung der Spiegelform), können wir auch eine reflektierende Beschichtung (der Prozess des Auftragens einer Beschichtung, die die Reflexionsleistung erhöht) auf die geformte Kunststofflinse anbieten.

Bei der Umstellung von Metall- oder Glaslinsen auf Kunststofflinsen gibt es neben der erwarteten Gewichts- und Kostenreduzierung auch technische Probleme wie die Haftfestigkeit, die kosmetische Qualität der Teile und die Schwierigkeit der Verarbeitung.

Ein weiteres Problem ist, dass bei der Herstellung von Kunststoffspiegeln der Spritzguss- und der Beschichtungsprozess manchmal von verschiedenen Unternehmen durchgeführt werden.

In diesem Fall,

● ist unklar, welcher Prozess die Ursache ist, wenn ein Teil/Produktfehler auftritt

● Es besteht die Gefahr einer falschen Ausrichtung oder Inkonsistenz zwischen den Prozessen, was zu einer Verschlechterung des kosmetischen Ertrags der Teile führen kann

und andere Probleme können auftreten.

Als Antwort auf diese Probleme nahm der Kunde einen Vorschlag des integrierten Systems von Toyotec an.

Dies ermöglichte die Realisierung von Kunststoffspiegeln unter Nutzung des Wissens über Formgebungs- und Beschichtungstechnologien, das Toyotec über viele Jahre hinweg aufgebaut hat.

Zukunftsperspektiven aufgrund der Auswirkungen und Veränderungen, die sich aus der Einführung des Systems ergeben

Kunststoff hat einen größeren Freiheitsgrad in Bezug auf die Form der Komponenten als Glaslinsen, und durch den Wechsel von Glas- zu Kunststoffspiegeln konnten wir die Anzahl der Komponenten reduzieren.

Wenn jedoch Formgebung und Beschichtung von verschiedenen Zulieferern durchgeführt werden, kommt es häufig zu Problemen wie instabiler Qualität und geringer Ausbeute.

Toyotec löst diese Probleme durch eine integrierte Produktion. Wir verhindern Probleme, die bei der kosmetischen Behandlung von Teilen und bei Umwelttests auftreten können, indem wir eine optimale Fertigung im Haus durchführen.

Darüber hinaus ist es uns gelungen, bisher schwer zu erreichende Präzisionsanforderungen (Oberflächengenauigkeit, Winkel) zu erfüllen, wofür wir von unseren Kunden viel Lob erhalten haben.

TOYOTEC's Lösungen

Wir verfügen über ein System, das es uns ermöglicht, Formgebung und Beschichtung von Kunststoffspiegeln aus einer Hand anzubieten.

Dieser integrierte Ansatz hat zu folgenden Ergebnissen geführt

●Leichtgewichtige, kostengünstige Kunststoffspiegel

● Lösung von Problemen mit der kosmetischen Ausbeute der Teile

Toyotec wird auch in Zukunft eng mit seinen Kunden zusammenarbeiten, um die am besten geeigneten Lösungen vorzuschlagen. Wir werden weiterhin die Erwartungen unserer Kunden durch die Herstellung hochwertiger Kunststoffspiegel erfüllen.

Related Solution-Application

Micro Cylindrical Lens fo

Was ist die Micro-Zylinderlinse?

Mikrozylinderlinsen mit kleinen R

Development Story “We wanted…

Specially Shaped Plastic

Challenges Before Implementation The…

Plastic Lens Units for So

Challenges Before Implementation The…

Glass Lens for Ophthalmic

Challenges Before Implementation The…

Reference Development Cas

Do you have any…

Custom Lens Unit for Ware

Challenges Before Implementation When…

Ultra Low Distortion Cust

Challenges Before Implementation When…

JP Phone: 0533-85-3000

JP Phone: 0533-85-3000