Fallstudien : Reduzierung der Arbeitsstunden des Kunden durch Bewertung optischer Linseneinheiten im Auftrag des Kunden

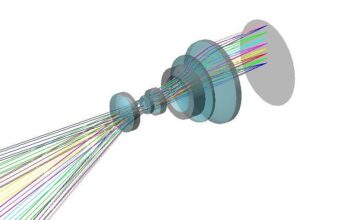

Among the industries in which TOYOTEC provides optical lenses and lens units are “sensors” and “robot cameras (machine vision)”.

We have continuously received inquiries and requests for problem solving from these industries in the current trend of automation and labor saving.

Evaluation issues for manufacturers of optical unit embedded products

Toyotec has consulted with our customers in a wide range of products; from standard catalog products to products with specifications that varies depending on what kind of end users our sensor manufacturing customers have. In recent years, the problem of product evaluation has often been raised as an issue for these manufacturers.

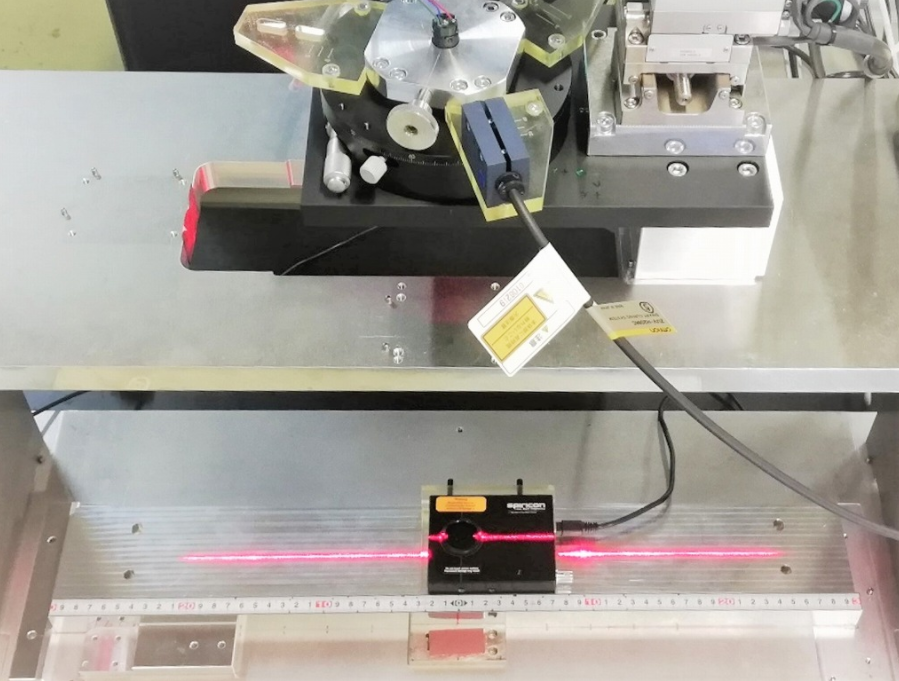

Example of optical system evaluation: Laser line generator lens

Increase in man-hours due to acceptance inspection for lens units

Generally, sensor manufacturers procure optical lenses and lens units from lens manufacturers, integrate them into their products, and then sells them. In recent years, there has been an increase in the number of cases where sensors with different specifications are required for each end-user’s factory line, and the product lineup has been increasing significantly.

In addition, in order to improve the cycle time of production lines, higher performance and more complex optical systems are required, and the man-hours and time required to evaluate the performance of products are increasing proportionally.

One particular issue that arises in this situation is that when a product evaluation is conducted within the customer’s company and a failure is found on a particular product, it is difficult to determine the cause of the problem and a great deal of time is required.

Even if the lens manufacturer delivers a lens of reliable quality for performance evaluation of the delivered lens alone, when assembled as a lens unit, it is another matter whether the optical system will work correctly when incorporated into the customer’s product. It is impossible to evaluate whether the final optical system unit has any problems or not without considering various conditions such as the work to be detected, the light source to be used, and the environment in which the sensor will be used. In many cases, assembly plants do not have sufficient facilities for evaluating optical systems, and in such cases, inquiries and evaluation requests must be made to lens manufacturers on a case-by-case basis.

As the number of products increases and product performance becomes more and more high-spec, it is taking too much time to find out where the problem lies and what specific parts should be reviewed if the problem is within the optical system. This is an urgent quality evaluation issue for some sensor manufacturers.

TOYOTEC’s mission is to assist in the evaluation of the final product.

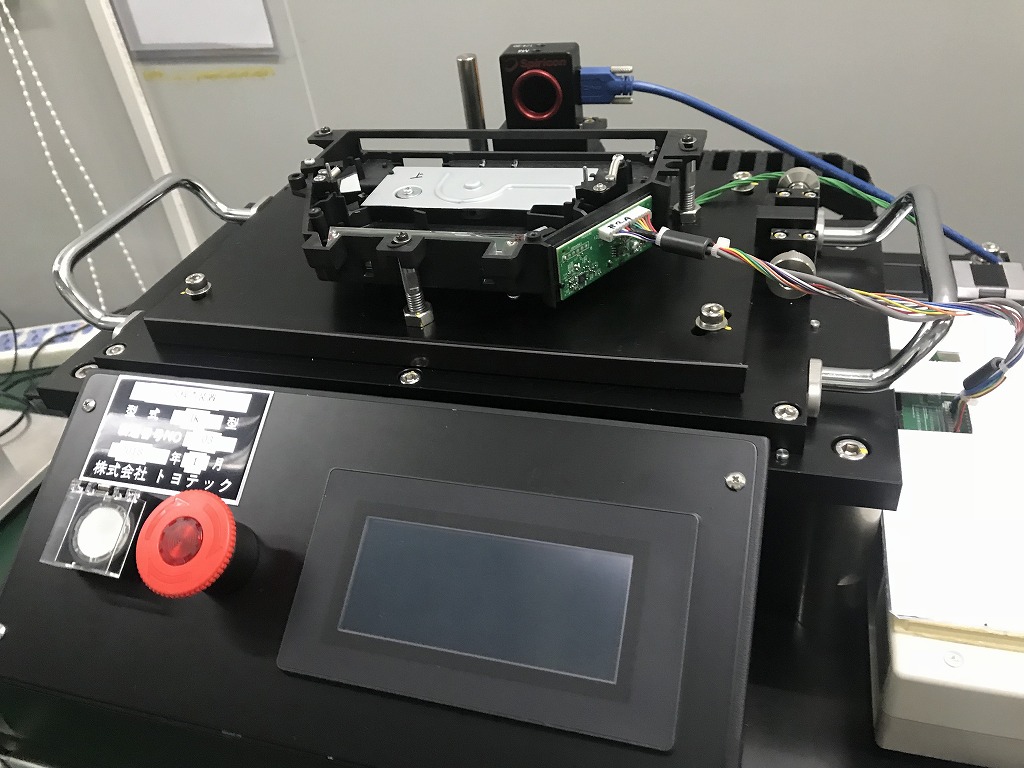

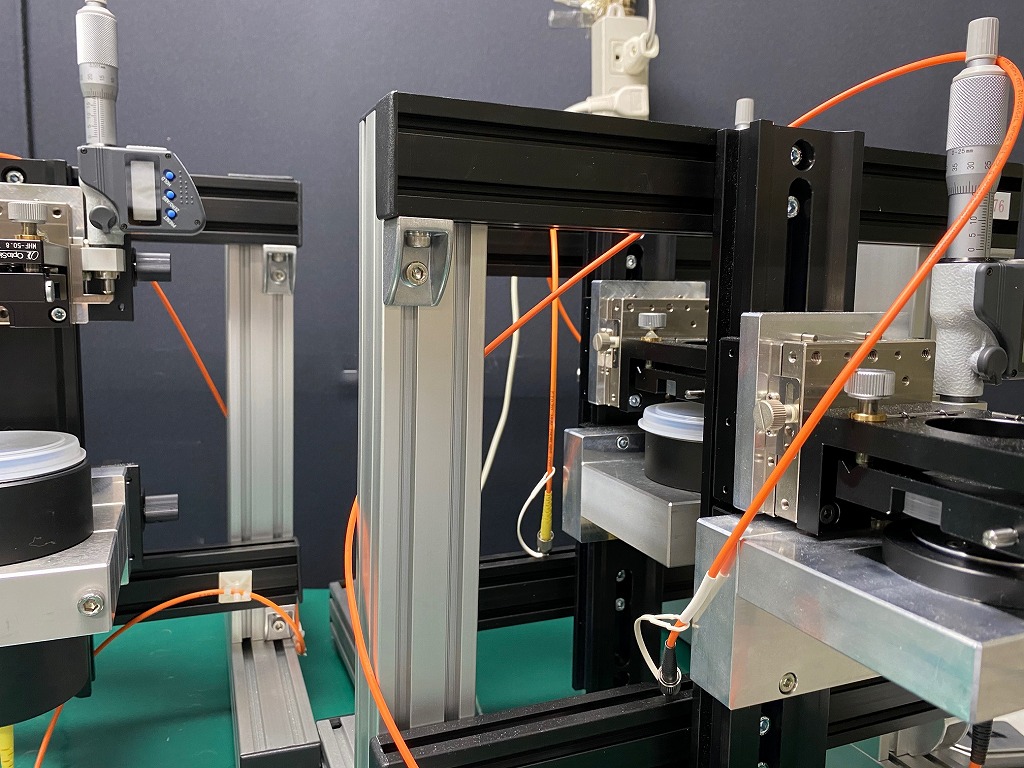

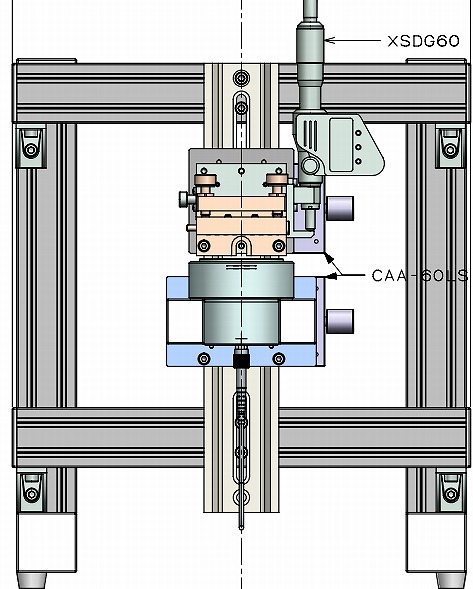

TOYOTEC is working on this issue to a level that ordinary lens manufacturers are not willing to go to. The above is an example of a special evaluation machine TOYOTEC manufactured for a customer’s individual optical system quality evaluation issue. TOYOTEC manufactured the evaluation machine according to the target workpiece and operating environment of the sensor.

In some cases, these custom-made evaluation machines are delivered to the customer’s factory for quality assurance, while in other cases, they are used internally by TOYOTEC to evaluate lens units (even to OEM products in some cases).

As a lens manufacturer, it is of course our job to produce lenses and lens units that meet customer specifications, but we also believe that our job is to guarantee the optical system of the “customer’s final product”.

Please feel free to contact TOYOTEC if you are experiencing quality assurance issues with your optical systems.

>> Click here for information on the results of evaluation machines.

JP Phone: 0533-85-3000

JP Phone: 0533-85-3000 Kontaktiere uns

Kontaktiere uns Language:

Language: